Mechanics

The amount of in-house production reaches 90% on our main business with snowmaking and track-setter products thereby we can deploy our deep and wide manufacturing know-how for other companies in the section of contract manufacture.

We construct all of our developments in-house with a 3D-CAD system, which we can use in customer projects, if an engineering solution is needed.

Our core competencies in the production can be divided essentially into three sections: machining, welding and module assembly.

As a result that we traverse the complete cycle from development to the finished product for our own devices, we can put ourselves very well in our customers place, which contributes to the optimum production solution.

A few basic facts to the sections:

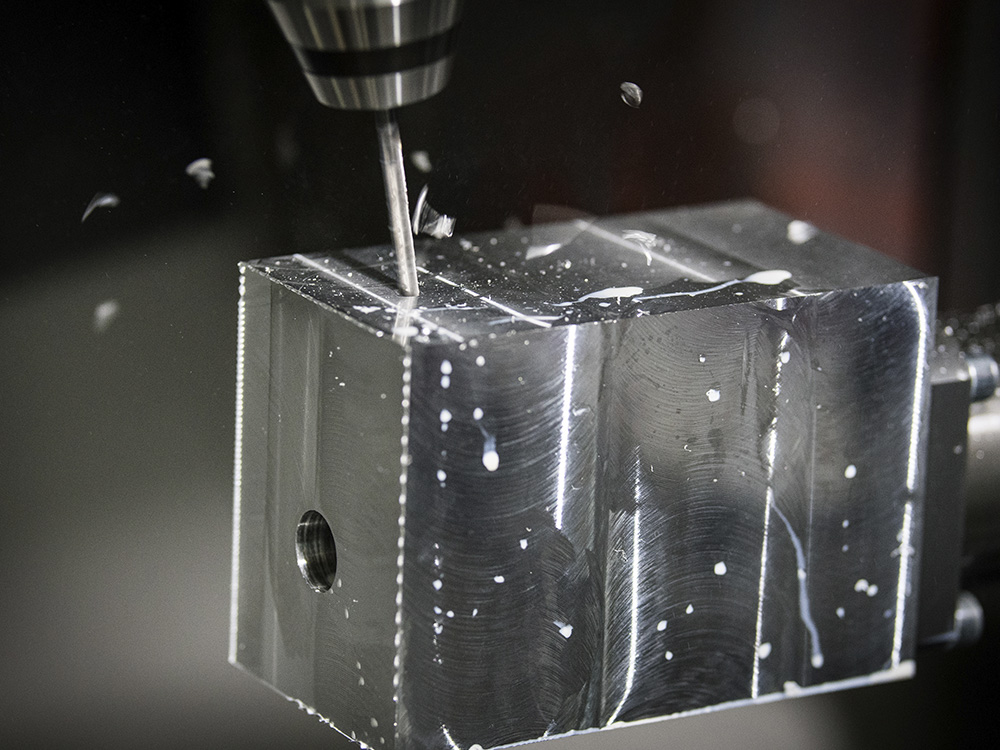

machining manufacturing (turning, milling up to 5 axes)

We construct all of our developments in-house with a 3D-CAD system, which we can use in customer projects, if an engineering solution is needed.

Our core competencies in the production can be divided essentially into three sections: machining, welding and module assembly.

As a result that we traverse the complete cycle from development to the finished product for our own devices, we can put ourselves very well in our customers place, which contributes to the optimum production solution.

A few basic facts to the sections:

machining manufacturing (turning, milling up to 5 axes)

- 3 turning machines with rod feeding

- 3 milling machines from 3 to 5 axes

- Processing of different materials such as aluminium, stainless steel, iron steel, nonferrous metal, plastic

- several hand-held welding torches

- welding robot system with double-rotary table with 1.5 m distance between centers

- welding of different materials such as aluminum, stainless steel, iron steel

- from small components to complete machinery and equipment

- very versatile with mechanical, hydraulic, pneumatic and electrical components